Laying our faith on the statistics that claim, the use of 3D printing in the construction market was at a modest price of $29 million in 2019. And the prediction that the world will witness a ten-fold growth by 2027 and reach the worth of $280 million. It becomes necessary to think about ways in which 3D printing can transform the construction industry, doesn’t it?

The most eye-raising, attention-seeking event on this side happened in 2015. Winsun Decoration Design Engineering built around ten residential houses in twenty-four hours! The scale and speed of this project had a tremendous impact on the upcoming projects in the field of 3D printing in the construction industry for the next five years. Due to this impact, construction decisions such as the one that was made in Dubai were minutely or majorly getting influenced by 3D printing.

The Prime Minister of the United Arab Emirates announced that around 25 percent of the city’s new buildings would be built using 3D printers. So, you can imagine how important 3D printing must be to the construction sector! And in the coming days, it could completely transform the fate and face of the way in which things are done in the construction industry. But how is that going to happen? Well, we have ten different ways in which that could happen.

1) Constructing a place at much lower costs

In the project that we did mention above, the cost of making those residential houses came around $5000. Can you imagine a house to be made with traditional manufacturing technologies at such a low cost? The major cost involved in 3D printing a construction site is, buying a 3D printer and the 3D printing material.

2) Material costs will decrease

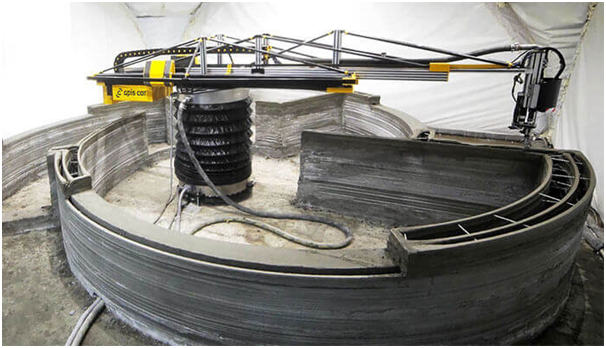

By building sites using 3D printers, you have a guaranteed way of using the precise amount of concrete needed for building a wall, floor, or any other part. There is no speculating about anything, instead, there are accurate calculations by software. This would also mean that the builder would not have to store anything in bulk and know the exact proportion to order. It would be sustainable as well as environment-friendly.

3) Construction would be quicker

As mentioned earlier, building ten houses can take only twenty-four hours by a 3D printer! It might be possible to build a ten-storeyed building in a day. And this benefit is because of the inherent nature of 3D printing i.e. layer-by-layer manufacturing. Once you design the complete model on 3D printing software and start printing, you need not worry about anything else. If you’ve never used a 3D Printing software before, read Pick3Dprinter’s list of the best free 3D modeling software, find one that suits you best and get going.

4) Injuries on-site can reduce by a significant amount

For building a construction site via 3D printing technology, you will need almost half, or an even lesser amount of labor than what you need by building it with traditional technologies. Considering the number of laborers would decrease, their interactions with each other would decrease and hence there would be lesser chances of dangers to their health and also injuries on-site. Because there would be free space.

5) Buildings will be more durable

In the first stages of construction, 3D printers focus a lot. This will lead to more durable buildings than the current one and hence repairs would be fewer. This will encourage more and more construction companies to invest on the foundational level and lesser on the maintenance.

6) The form of the building will improve

Odd and typical building structures that are difficult and even impossible to make using traditional technologies, will become possible. Because all you need to do with 3D printing is make sure your 3D design file is flawless.

7) More brand-specific industry

3D Printing is all about customization. And so is branding. Using this technology more companies will be able to develop their signature, no matter how complex it is, on the buildings they make. This will in turn give them a unique identity in such a competitive market.

8) Hiring 3D printers for construction

Like we have companies that let other companies hire construction equipment, currently, we will have companies that will offer 3D printers for rent, in the future. In fact, if the industry develops in a full-fledged manner there’ll be more and more specific companies and printers, for building architectural monuments, buildings, commercial spaces, etc.

9) More dynamic market

This is in context with the previous point. If the market develops in such an open manner, it will have to welcome new players in it. And that would mean that the market will be more mobile, and more dynamic than what it currently is. Because there would be a little less dependency and a lot more freedom.

10) Increase in commercial spaces

We’ll have to consider the example of Dubai for understanding this prediction. The state hosts the world’s first 3D printed office block in which people currently work. Seeing its efficiency, more and more countries are setting it as an ideal and trying to experiment with the same idea. Of course, this doesn’t mean undermining the idea of an increase in residential spaces as well. But with a completely functional commercial building, the developers on this have a little more edge than the residential side.

The Conclusion

There are numerous advantages of 3D printing technology which makes it a very suitable technology for the construction industry. It lets you manage the complete production process from the very first start. And eliminates all the flaws of current manufacturing technology. Also, 3D printed structures are more eco-friendly than the ones made from traditional manufacturing technologies because they do not cause any material waste.

Having stated so, the construction industry will need 3D printing technologies such as SLS, Binder Jetting, and Material Jetting to pick up and become more accessible. Only then the future in which 3D printing is the mainstream manufacturing technology employed for developing construction structures seems possible. But for once, this technology has developed enough to catch your attention and make you ponder on what its potential are!